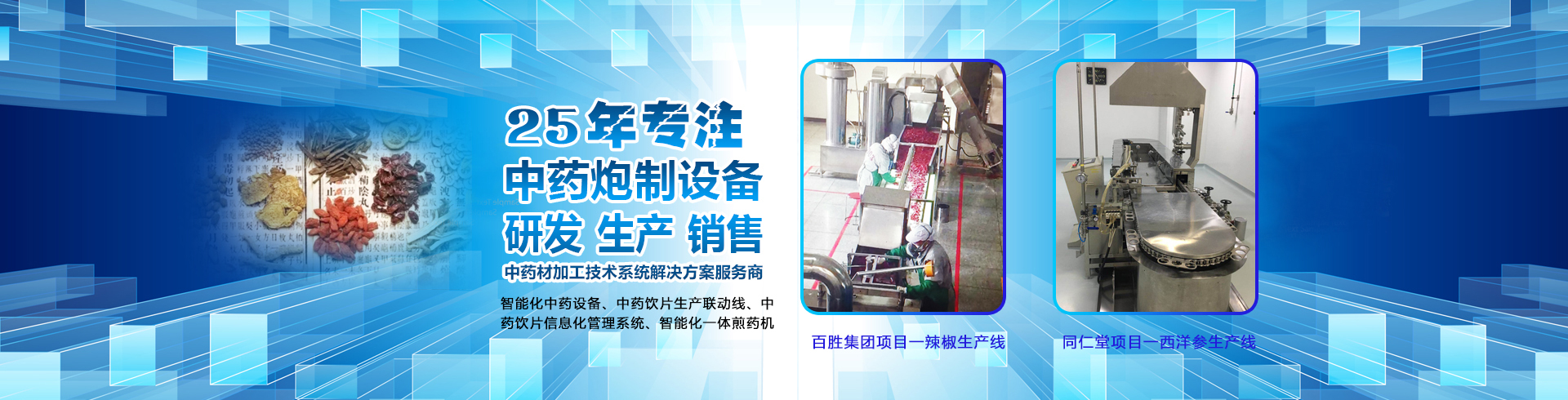

杭州海善制药设备有限公司根据饮片企业全新生产线的技术要求;经过与饮片生产方技术人员的充分沟通,结合我公司的研发、生产、制造实际情况。设计了整套的符合中药配方颗粒提取的中药材前处理加工生产线。以满足饮片企业对生产流水线的工艺具体要求,此生产线的设计代表了国内饮片企业zui高水平。根据中药饮片的加工炮制特性,把所有加工炮制设备都用流水线方式实现显然不现实,也未必科学。但可以把一部分设备用输送机连成流水线。也有些可以减压输送环节,以降低劳动强度,提高生产效率,降低生产成本,优化产品生产工艺流程。

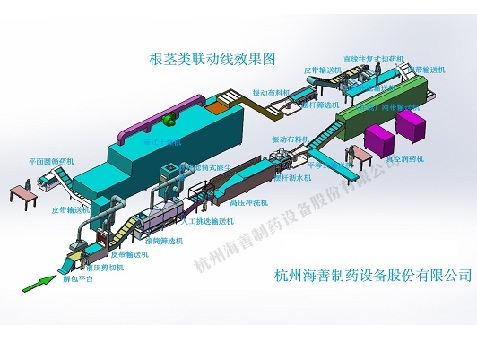

根茎类联动线工艺流程说明:

自动上料拆包平台(上方除尘点)→液压剪切机(上方除尘点)→皮带输送机→滚筒筛选机→人工挑选输送机→鼓泡高压喷淋清洗机→振动筛选机→润药机→网带输送机→切药分流输送机→直线往复式切药机→振动筛选机→匀料机→带式干燥机→皮带输送机→柔性支承斜面筛选机→包装

Hangzhou Hai Shan Pharmaceutical Equipment Co., Ltd. is based on the technical requirements of the new production line of the beverage enterprise, and through the full communication with the technical personnel of the production of the decoction pieces, combining with the actual situation of R & D, production and manufacture of our company. A set of pre-processing and processing line of Chinese herbal medicine which is compatible with Chinese medicine formula granules was designed. In order to meet the specific requirements of the production line, the design of the production line represents the highest level of domestic enterprises.

According to the processing characteristics of Chinese herbal pieces, it is obviously unrealistic and not scientific to implement all processing equipment by means of pipeline. But a part of the equipment can be connected to the assembly line by conveyor. Some can also direct the material from one equipment to another, which can reduce the intensity of labor, improve the production efficiency, reduce the production cost and optimize the production process.

The production line of the flower plant line:

Unpacking, hydraulic truncation, cylinder screening, selection, spray cleaning, drainage, cutting, drying, cooling, transportation, and so on.